“Crescent Manufacturing Has Its Sights Set On The Future”

By Ginger Doherty, Vice President Sales, Crescent Manufacturing

Early History

Crescent Manufacturing started in 1960 in a garage on Crescent Lake in Southington CT. There were 3 partners at that time. They were all businessmen but did not have any experience in fastener manufacturing. With a lot of ingenuity and a “can do” attitude”, they learned the business.

Seven years later the three owners had to move into a larger facility. In 1967 Crescent moved to its current location in Burlington, Connecticut. A large apple orchard consisting of eleven acres was purchased from a local farmer. An 8700 square foot building was erected on the site. Since then there have been several additions. The current facility is over 25,000 square feet with plenty of room for expansion in the future.

Over the years there have been a number of owners, both silent and active. Even though the company has changed hands a few times many of the employees have stayed the same. Several employees have 20 or more years with the company. Crescent’s very first employee retired in 2009. One of the three original owner’s daughters, Kim Guerrette, retired in 2015 after serving with the company for 38 years. The many experiences that have been passed down over the years have developed Crescent into a highly reliable source for precision metal fasteners in many different markets.

Recent History

The most recent purchase in November 2005, by Steve Wilson, has bought a fresh perspective to Crescent. Steve has an engineering background and has worked for several manufacturing companies prior to joining the Crescent team. He has a strong interest in research and development. To that end, there is a never-ending search for opportunity, continuous growth & expansion of our product lines. The most recent additions are the NAS1802 and NAS1620-NAS1626 series. Along with those two product additions, Crescent has also taken another look at other materials and has been able to add A286 stainless steel, 2024 Aluminum, and 6061 Aluminum to the materials that the company offers customers. This means previous “no quotes” are now quoted in these new product series as well as in product lines Crescent has always quoted. Crescent continues to pursue new product line additions as well as new materials with which to work.

The most recent purchase in November 2005, by Steve Wilson, has bought a fresh perspective to Crescent. Steve has an engineering background and has worked for several manufacturing companies prior to joining the Crescent team. He has a strong interest in research and development. To that end, there is a never-ending search for opportunity, continuous growth & expansion of our product lines. The most recent additions are the NAS1802 and NAS1620-NAS1626 series. Along with those two product additions, Crescent has also taken another look at other materials and has been able to add A286 stainless steel, 2024 Aluminum, and 6061 Aluminum to the materials that the company offers customers. This means previous “no quotes” are now quoted in these new product series as well as in product lines Crescent has always quoted. Crescent continues to pursue new product line additions as well as new materials with which to work.

Acquisition of Perfection Screw

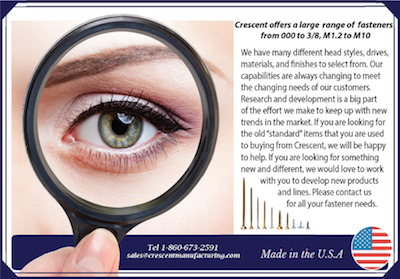

Like other manufacturers, Crescent has had to deal with a challenging economy. Part of this strategy was to acquire Perfection Screw including many of its machines and tooling and as well as its customers. By taking this action, Crescent has grown its capabilities in both size and length of the screws and rivets that Crescent is able to manufacture. Previously Crescent’s range had only been “00” to 5/16 diameter, and 2 inches in length. Crescent is now able to manufacture parts from “000” to 3/8 diameter and up to 3 inches in length. This also applies to Crescent’s metric lines (M1 to M10 and up to 76MM in length) As Crescent has added machines, it created new positions within Crescent. Crescent required more people to run these machines, more qualified personnel, and newer more technical, and sophisticated inspection equipment.

Raw Material

Crescent now warehouses all our raw material in-house. This reduces our storage costs and completely eliminated lost time waiting for material to come from a previous offsite public warehouse located several miles away. Crescent typically warehouses over 250,000 lbs. of raw material in 14 different materials in as many as 50 diameters. All our material is mercury and asbestos-free, DFARS compliant, and conflict minerals compliant as well.

in-house tooling at Crescent Manufacturing

In House Tooling Capability

Crescent now warehouses all our raw material in-house. This reduces our storage costs and completely eliminated lost time waiting for material to come from a previous offsite public warehouse located several miles away. Crescent typically warehouses over 250,000 lbs. of raw material in 14 different materials in as many as 50 diameters. All our material is mercury and asbestos-free, DFARS compliant, and conflict minerals compliant as well.

Manufacturing

Crescent utilizes over 100 pieces of precision equipment in its manufacturing processes to produce highly engineered metal fasteners. Beginning with coiled wire of various materials and diameters, the heading process is the first step. Crescent’s cold headers are several different sizes and are grouped in manufacturing cells. The next step is slotting if required. If the parts don’t need to be slotted, the next step would be threading. Special lubricants are used in each manufacturing operation. These lubricants are specially designed for each cold heading step. Lubricant must be removed through a wash operation between each cold heading process, and before the parts go to the final finishing process.

Machine Rebuild Program

Crescent rebuilds and services our own machinery. We have a regular maintenance program and rebuild program for our machines. Constant machine improvements are made to increase efficiency and production throughout our processes.

Outside Processing and Testing

Crescent has a large variety of outside processes that we offer including heat treating, plating, head drilling, and captivation. Most of our vendors are NADCAP, AS9100, and or ISO certified as they apply. Certifications for all these processes are provided to our customers on request. We also have several independent labs that we use to verify and certify the products that we manufacture. These services make our quality unsurpassed in the industry.

Quality

We take great pride in the quality of our products and to that end Crescent holds and maintains certifications to AS9100 Rev C., ISO9001-2008, and we are also ITAR registered. We provide copies of these certifications on request. We also meet the most demanding specifications including MIL-I-4508A for quality systems and MIL-STD-45662A for gage calibration. We have been approved for Class 2A and 3A threaded fasteners since 1996 by the Defense Supply Center. We comply with US and European quality requirements including DFARS, Conflict Minerals, REACH, RoHS, and many others.

Markets

Crescent services many different industries including the military, aerospace, and firearms. On the commercial side of the industry, we are involved in computer technology, electronics, medical equipment, industrial, telecommunications, and many more. We are always looking for opportunities and our team will always help with custom projects for our customers.

Summary and Future

Crescent has a bright future and ever-expanding growth potential. Crescent now has a larger sales staff. There are four inside sales associates, and eleven (11) outside sales representatives, here and abroad. The sales department’s goal is to turn around quotes in 24 hours or less whenever possible. Crescent is always happy to quote multi-year contracts and engineered specials to print. Crescent’s global presence has grown with distributors now on 5 continents.

Read more About Crescent Manufacturing.

The most recent purchase in November 2005, by Steve Wilson, has bought a fresh perspective to Crescent. Steve has an engineering background and has worked for several manufacturing companies prior to joining the Crescent team. He has a strong interest in research and development. To that end, there is a never-ending search for opportunity, continuous growth & expansion of our product lines. The most recent additions are the NAS1802 and NAS1620-NAS1626 series. Along with those two product additions, Crescent has also taken another look at other materials and has been able to add A286 stainless steel, 2024 Aluminum, and 6061 Aluminum to the materials that the company offers customers. This means previous “no quotes” are now quoted in these new product series as well as in product lines Crescent has always quoted. Crescent continues to pursue new product line additions as well as new materials with which to work.

The most recent purchase in November 2005, by Steve Wilson, has bought a fresh perspective to Crescent. Steve has an engineering background and has worked for several manufacturing companies prior to joining the Crescent team. He has a strong interest in research and development. To that end, there is a never-ending search for opportunity, continuous growth & expansion of our product lines. The most recent additions are the NAS1802 and NAS1620-NAS1626 series. Along with those two product additions, Crescent has also taken another look at other materials and has been able to add A286 stainless steel, 2024 Aluminum, and 6061 Aluminum to the materials that the company offers customers. This means previous “no quotes” are now quoted in these new product series as well as in product lines Crescent has always quoted. Crescent continues to pursue new product line additions as well as new materials with which to work.

there was usually a book to be found that increased my knowledge I could learn on my own. Technical books have always been a great resource, whenever I had an application engineering problem to solve. After eight formative years in the business, I accepted an application engineering position with Crescent Manufacturing in Burlington, CT. Established in 1960, it had been owned by three partners, who for twenty years poured heart and soul into Crescent to grow the company. Having sold the business and retired, it was under new leadership of Dick Hrinak, with a knowledgeable and skilled sales and manufacturing team. Those were a technically charged and exhilarating times.

there was usually a book to be found that increased my knowledge I could learn on my own. Technical books have always been a great resource, whenever I had an application engineering problem to solve. After eight formative years in the business, I accepted an application engineering position with Crescent Manufacturing in Burlington, CT. Established in 1960, it had been owned by three partners, who for twenty years poured heart and soul into Crescent to grow the company. Having sold the business and retired, it was under new leadership of Dick Hrinak, with a knowledgeable and skilled sales and manufacturing team. Those were a technically charged and exhilarating times. which is usually fasteners that they have difficulty finding. So, once again you have asked and we have tried to accommodate your requests.

which is usually fasteners that they have difficulty finding. So, once again you have asked and we have tried to accommodate your requests.