Manufacturing is making a gradual comeback in the United States. "Reshoring", as many call the recent trend of manufacturing relocating from overseas back to the U.S., is occurring in a steady stream of steps. Numerous examples of reshoring are being regularly reported in the media. This includes K'Nex Brands LP, a toy manufacturer, bringing back most of its plastic building toy manufacturing to its factory in Hatsfield, Pennsylvania from subcontractors in China reported in the "Wall Street Journal " March 10, 2013.

Also in March, "kiplingers" cited "American companies ranging from Otis Elevator to Frisbee maker Wham-O have repatriated at least some manufacturing to the U.S. Last year, General Electric revitalized two factories in Louisville, Kentucky to produce water heaters that have been made in Chian and refrigerators formerly made in Mexico."

"Kiplingers" continues reporting that "As part of a $1 billion investment, GE will also begin making dishwashers in the U.S. that are not currently made here, and it will add more refrigerators and dishwashers to the U.S.-made mix. " In a study co-authored by Michigan State University, 40% of U.S. manufacturers surveyed reported a reshoring trend in their industries.

Not only will Apple Computer begin producing some of its Mac computers in the U.S. - the first time in a decade- but China's Lenovo Group Ltd. plans to begin manufacturing some of its personal computers in North Carolina later this year.

There is a paradigm shift underway in global manufacturing. While China has been known as the "World's factory", this is beginning to change for a number of reasons. Chinese wages have increased ninefold-- that's right!--almost a factor of ten times higher than what they were in 2000. Chinese wages are now accelerating about 15% annually compared to relativity stagnant wages in the United States.

According to the “Washington Post” April 30, 2013, this wage gap has decreased from a difference of $17 per hour in 2006 to an estimated $7 per hour by 2015. This difference can be made up for by logistical considerations and additional flexibility that U. S. based manufacturing affords. In fact, this additional flexibility is one reason why China’s Lenovo Group, cited above, is expanding manufacturing in the United States.

The Chinese Yuan has appreciated 25% against the U. S. dollar since 2000. The Yuan is currently appreciating about 1% per quarter which doesn’t sound like much but this is compounding over time. An appreciating Yuan effectively means that a product manufactured in the United States is that much less expensive and therefore relatively more competitive than the same product manufactured in China.

Shipping costs between China and the United States are now double what they were in 2009. Quality continues, in too many instances, to be questionable and erratic. With the long chain between China and the United States, when there is a quality concern or issue, there is generally a large inventory of products already in transient. Good luck dealing with communication in getting a problem resolved halfway across the world while one waits for a replacement shipment and a production line is at risk of shutting down.

A second paradigm shift during the last few years is the availability of cheap natural gas in the United States. This is a result of the abundance of U. S. shale gas and new technology that is now available to economically

extract natural gas. Based on cheap U. S. natural gas, there is now a brand new generation of petrochemical plants being constructed in the United States. This would have been unthinkable even a few years ago. In fact, shale gas has made the U. S. the second most cost-competitive place to make ethylene and other basic petrochemical feedstock behind the Middle East (“The Shale Gale” “Chemical and Industry News” April 8, 2013).

Shale gas dominated discussions at the HIS World Petrochemical Conference held in March at the Hilton Americas Hotel in downtown Houston. According to the “Chemical and Engineering News—C&EN”, “one speaker after another analyzed from every perspective the new world order in petrochemicals brought about by shale gas production.” C&EN goes on the report that this revolution in shale gas production has “driven down the cost of making petrochemicals in the U. S. by 50%. This cost advantage is expected to lead to a 60% expansion of the U. S. chemical industry with billions and billions of dollars being invested in petrochemical plants. Numerous companies are involved in this including Exxon Mobil, Shell, Dow Chemical, and many others.

Relatively inexpensive petrochemicals are another factor beginning to drive U. S. based manufacturing. The cover of “Barron’s” January 28, 2013: “Made in America---Manufacturing is at the beginning of an amazing comeback in the U. S., powered by low-cost natural gas at home and rising wages in Asia. What it means for investors” Barron’s reports that companies like Caterpillar, Ford and others are making more of their goods in the United States. And it isn’t just American companies. Samsung Electronics (Korea) plans a $4 billion semiconductor plant in Texas. Airbus SAS is building a factory in Alabama and Toyota plans to export minivans made in Indiana to Asia.

Mr. Antoine van Agtmael, an “investor visionary” and analyst who invented the concept of “emerging markets” according to “Barron’s” (April 19, 2013) estimates that so far at least 200 companies have relocated manufacturing plants from offshore to U. S. locations. Mr. van Agtmael went on to comment for “Barron’s” that “A decade ago, nine out of 10 companies would tell you they were thinking about building their next plant in China.” “Today it’s more like three out of ten, and maybe even five out of 10, say they want to build in the U. S.”

The trends are clear, for a number of reasons; the world manufacturing landscape is changing. An increasing number of global companies are looking toward the United States for manufacturing.

This article was prepared by Steve Wilson, Chairman of Crescent Manufacturing located in Burlington, Connecticut. It is based on a presentation that he made at the New England Fastener Show in April 2013. Crescent Manufacturing manufactures a wide range of cold headed metal fasteners ranging in size from 00 through 5/16” (M1.4 through M8) with lengths up to 3” (76mm). Crescent makes all of it products in the United States and is AS9100-C, ISO9001, QSLM, and ITAR certified. Crescent Manufacturing may be contacted at 860-673-2591.

This was Governor Malloy's first public appearance following his inauguration.

This was Governor Malloy's first public appearance following his inauguration.

For over 50 years Crescent Manufacturing has been supplying fasteners and miniature screws through domestic and international distributors.

For over 50 years Crescent Manufacturing has been supplying fasteners and miniature screws through domestic and international distributors.

In 1967 with three new employees, four headers, three slotters, and five thread rollers, Crescent moved from its present location in Burlington, Connecticut. The entire manufacturing area didn't even take up one-third of the then 15,000 sq. ft. building, but they planned for room to grow. One of those three employees was Norman Provencher, now Crescent's Quality Manager and our senior employee with 42 years of service. Norm was making great money back then $3.00/hr running ten machines. After a couple of years, he asked if he might have a raise and was told "we can give you another nickel, but you'll to run more machines." Ah the good old days!

In 1967 with three new employees, four headers, three slotters, and five thread rollers, Crescent moved from its present location in Burlington, Connecticut. The entire manufacturing area didn't even take up one-third of the then 15,000 sq. ft. building, but they planned for room to grow. One of those three employees was Norman Provencher, now Crescent's Quality Manager and our senior employee with 42 years of service. Norm was making great money back then $3.00/hr running ten machines. After a couple of years, he asked if he might have a raise and was told "we can give you another nickel, but you'll to run more machines." Ah the good old days!

Mr. Richard Green, CFO, as stockholders. 2005 brought the most recent change to Crescent. Mr. Steve Wilson, now Chairman, found Crescent to be that small company he was looking to buy, right when they were looking to sell. Steve saw the potential that Crescent has with our ever-evolving plan. Dick and Rick continue with Crescent, along with all the people you have come to know. We have many long-term employees, most with over ten years of service and experience. Our sales department consisting of Marion Lederman (30 years), Ginger Doherty (11 years), and Aaron Stevenson (3 years). Their knowledge of our product and manufacturing capabilities are at your disposal. Bruce Penn (30 years), VP of Manufacturing, works with Aron to get your orders out on time - at least most of the time.

Mr. Richard Green, CFO, as stockholders. 2005 brought the most recent change to Crescent. Mr. Steve Wilson, now Chairman, found Crescent to be that small company he was looking to buy, right when they were looking to sell. Steve saw the potential that Crescent has with our ever-evolving plan. Dick and Rick continue with Crescent, along with all the people you have come to know. We have many long-term employees, most with over ten years of service and experience. Our sales department consisting of Marion Lederman (30 years), Ginger Doherty (11 years), and Aaron Stevenson (3 years). Their knowledge of our product and manufacturing capabilities are at your disposal. Bruce Penn (30 years), VP of Manufacturing, works with Aron to get your orders out on time - at least most of the time.

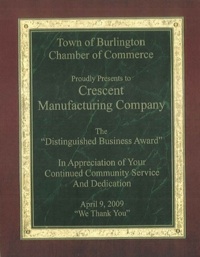

nominated Crescent Manufacturing for the honor and the award.

nominated Crescent Manufacturing for the honor and the award.