Originally Posted July 2013

Steve Wilson, Chairman of Crescent Manufacturing, quoted in July issue of “Global Fastener News”  concerning how to buy fasteners and U.S. reshoring. Excerpts from the New England Fastener Show panel discussion held in June 2013 in Sturbridge, Massachusetts

concerning how to buy fasteners and U.S. reshoring. Excerpts from the New England Fastener Show panel discussion held in June 2013 in Sturbridge, Massachusetts

PERSPECTIVE - Werner, Swain & Wilson: How to Buy Fasteners

Have a company purchasing philosophy, don't be wooed by small price differentials and learn the product – not just the part numbers – are suggestions from a New England Fastener Distributors Association conference session on " How to Buy Fasteners."

Panelists Ed Werner of EZ Sockets, Doug Swain of Atlantic Fasteners and Steven Wilson of Crescent Manufacturing offered tips during the session moderated by GlobalFastenerNews.com editor John Wolz.

Following are excerpts on How to Buy Fasteners:

Werner said the first step is for buyers for distributors to understand the company goal is to resell fasteners for a profit.

"All buying decisions must be in best interest of our company," Werner said. Each company needs to develop a purchasing philosophy.

Werner advised fastener buyers to avoid conflict of interest.

Fastener buyers should get to know suppliers, Werner said. "Interview your vendors. Visit them to evaluate their capabilities."

Werner recalled visiting Asian fastener manufacturers who claimed to be the "biggest and the best," but were operating out of 'chicken coops' and using old-fashioned digital scales. "If I didn't go there, I wouldn't know."

Find out what the return policy is before buying and test products – especially from a new supplier.

Talk to your suppliers to see if they can supply what you need in product, quality, quantity, and delivery. Check their past performance.

Who carries the insurance when goods are in the port during a monsoon? Werner asked.

Swain urged fastener buyers to "learn the language." That includes abbreviations, units of measure and terms of sale.

"Read industry articles," Swain suggested. "Stay current about acquisitions and mergers" as those may effect supply.

Create a database of the companies with the expertise in your niche.

"Keep updated," Swain pointed out. Brighton Best once only sold socket products.

Develop a relationship with suppliers. "As a distributor, your suppliers are teammates."

It isn't just price, Swain pointed out. The location of the shipping point, payment terms, and past performance of suppliers are vital factors.

Wilson's top advice is to "communicate, communicate, communicate," via face-to-face, by telephone or email/fax.

Wilson emphasized the need to "specify all requirements at the time of the quote."

Prints are necessary for non-standard parts, Wilson added. And be certain you have the current revisions of the print. Revision "A" is no longer good if you need "B" or "C."

If DFARS (Defense Acquisition Regulations System) is required it also should be specified upfront.

Wilson quoted an email from the under secretary of defense handling DFARS stating specialty metal fasteners manufactured in China cannot be certified to DFARS.

Wilson encouraged fastener buyers to diversify suppliers – "especially if buying offshore" – to assure supply.

Watch for possible domestic sources. Wilson pointed out there has been a nine-fold increase in wages in China since 2000; shipping costs have doubled since 2009; U.S. natural gas is cheaper; the Chinese Yuan has appreciated 25% against the U.S. dollar since 2000.

"Reshoring to U.S. manufacturers is here and now," he declared.

"Communicate!!!" Wilson said in summarizing his advice. "State the requirements in the beginning – at the time of the quote." ©2013 GlobalFastenerNews.com

This was Governor Malloy's first public appearance following his inauguration.

This was Governor Malloy's first public appearance following his inauguration.

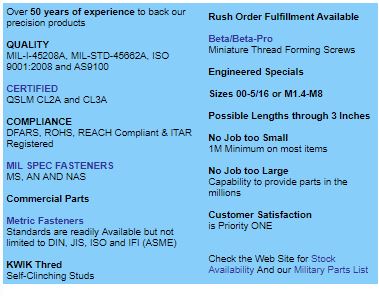

For over 50 years Crescent Manufacturing has been supplying fasteners and miniature screws through domestic and international distributors.

For over 50 years Crescent Manufacturing has been supplying fasteners and miniature screws through domestic and international distributors.